Dress Shirt Size Chart: A Simple Guide for New Designers

New to shirts?

This no-fluff guide explains the dress shirt size chart in plain English—what each column means, the basic grading (“jumps”) used in North America, how barcodes work, and how to build a clean chart that factories and shoppers both understand. (Want a fast way to make tables? Try this size table builder.)

1) What is a dress shirt size chart?

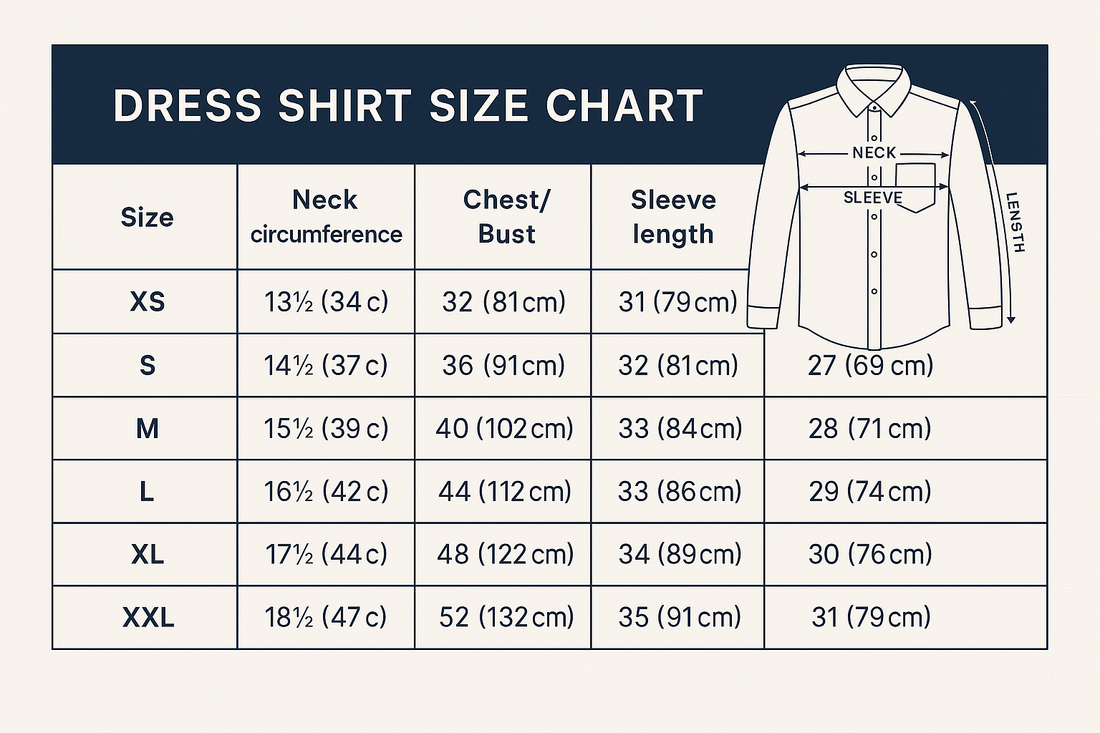

It’s a table that describes the body you want the shirt to fit, not just the garment. A beginner-friendly chart usually includes:

- Neck – around the base of the neck (where the collar sits).

- Chest – around the fullest part of the chest, tape level at shoulder blades.

- Waist – natural waist, above hipbones.

- Shoulder width – back, point-to-point.

- Sleeve length – center back neck → over shoulder → to wrist.

- Shirt length – high point of shoulder to hem.

- Fit – Slim, Tailored/Athletic, Regular/Classic, sometimes Relaxed.

Retail tags show either neck × sleeve (e.g., 15.5 × 34) or alpha (S–XXL). Your chart should map both to the same body measurements and offer cm/inch.

2) Core shirt types (fits) you’ll meet

- Slim – close to the body, minimal ease.

- Tailored/Athletic – broad shoulders/chest, trimmed waist.

- Regular/Classic – straighter sides, more room at midsection.

- Relaxed – extra ease for casual styling.

- Tall / Short – same chest/neck as base size with longer/shorter sleeves and body.

Collar styles (spread, point, button-down) do not change the chart; fit and sleeve options do.

3) North-American grading (“jump”) rules—just the basics

Use these as a starting point and adjust later:

- Neck: steps of 0.5 in (14.0 → 14.5 → 15.0…).

- Sleeve: grouped lengths 32/33, 34/35, 36/37 (~1–2 in steps).

-

Alpha sizes (S–XXL):

- Chest +2 in per size

- Waist +2 in per size

- Shoulder +0.5 in per size

- Shirt length +0.5–1.0 in per size

- Tall: body length +1–1.5 in and sleeves +1 in (Short is the reverse).

- Fit deltas (vs Regular): Slim −2 in chest/waist ease; Athletic +1 in shoulder, −1–2 in waist; Relaxed +2–3 in ease.

Always write tolerances on the chart (e.g., chest ±0.5 in / 1.3 cm). QC needs a pass/fail rule.

4) Barcodes: how many systems, and what logic?

There are four you need to know. Only one is the store checkout standard in the U.S./Canada.

-

UPC-A (12 digits, GS1 US) – retail POS standard in North America.

- Rule: one UPC per variant (style + color + size/sleeve/fit).

- Structure: manufacturer prefix + your item reference + check digit.

- Note: the UPC doesn’t “store” the size text—you assign a different item reference for each size.

- EAN-13 – used outside North America. If you sell globally, map each variant to an EAN.

- GS1-128 / Code 128 – carton/warehouse labels, not POS. Can include GTIN + quantity/lot.

-

Internal SKU / QR – your human-readable code for picking and returns.

- Simple pattern example:

STYLE-COLOR-FIT-NECKSLV→DR01-NVY-T-15534. - Map each SKU to a UPC (or EAN) in your PIM/ERP.

- Simple pattern example:

Takeaway: in North America, give every variant its own UPC, and use your SKU to show the size logic humans need.

5) How to choose (or build) the best dress shirt size chart

- Start with the body: use U.S. body data if selling in North America; make EU/Asia versions later if needed.

- Fix your fit story: clearly separate Slim / Tailored / Regular / Relaxed with stated ease.

- Cover the real size run: neck 14.0–18.5, sleeve 32/33–36/37, and Tall/Short if height drives returns.

- Explain how to measure: add one simple diagram and short text.

- Show conversions: neck × sleeve ↔ alpha; cm/inch toggle.

- Lock tolerances: publish them on the chart; factories will follow it.

- Version control: when grading changes, update patterns, labels, and barcodes together.

Need a tool to avoid mistakes? Use the size table builder.

6) Quick body-type mapping (who fits what)

- Slim – V-shape body, smaller waist-to-chest difference, wants a close look.

- Tailored/Athletic – broad shoulders/chest, tapered waist.

- Regular/Classic – straight torso, more room at waist and midsection.

- Relaxed – fuller builds or casual drape.

- Tall/Short – same neck/chest as base size, lengths adjusted for height.

7) Why the size chart matters in the factory

- Pattern grading: defines how each size grows (e.g., chest +2 in per alpha size).

- Marker making & fabric yield: predictable jumps reduce waste and cost.

- Quality control: inspectors measure against your tolerances.

- Labels & shipping: neck labels, hangtags, stickers, cartons, and barcodes must match the same chart—this prevents mis-ships.

8) Why designers love a solid chart

- Clear design envelope: known ease per fit keeps silhouettes consistent.

- Regional blocks: US/EU/Asia charts share one “fit story” but respect local bodies.

- Merch math: you can plan hero sizes (e.g., 15.5 × 34) and sleeve pairs to stock.

- Lower returns: repeat buyers remember their neck/sleeve pair and rebuy fast.

9) A simple workflow you can copy

- Define the dress shirt size chart (body columns, fits, tolerances).

- Create a readable SKU pattern and map each SKU to a UPC (or EAN).

- Publish a shopper-friendly table on PDPs with a measurement diagram and unit toggle.

- Keep one dated master; update patterns, labels, barcodes together.

- Build charts faster (and cleaner) with this size table builder.

Bottom line: A good dress shirt size chart is your agreement between customers, factory, and retail systems.

Keep the columns simple, the jumps standard, the barcodes unique per variant, and the instructions crystal clear—and your fits (and reviews) will improve quickly.